NAOJ GW Elog Logbook 3.2

[Shalika, Gabriella]

The setup was modified and two beam splitters were added (before and after LCs). The measurement to calibrate the beam splitters (both reflection & transmission) were taken as well (done without LCs).

What I did:

I fited the resuts of IP's resonant frequency to theoretical value.

The equation used for fitting was atttached.

f is IP's resonant frequency.

k_e is spring constant of IP's flex joint .

k is s anti spring constant.

g is gravity constant.

l is length of IP.

m_0 is mass of IP.

M is weight on IP.

From fitting, m_0 is 1.08 kg, k_e is 131 N/m, l is 2.48 m.

The results and fitting picture was as follows.

X-axis is weight on IP top, y-axis is IP's resonant frequency.

What we did:

We diagonalized the matrix of IP, and checked how much diagonalization was.

The matrix's values form LVDTs to imaginally L-axis and T-axis were as follows.

| L | T | |

| H1 | +0.20 | -0.04 |

| H2 | -0.07 | -0.12 |

| H3 | -0.09 | +0.13 |

The matrix's vakues from L-axis and T-axis to actuators were as follows.

| A1 | A2 | A3 | |

| L | -2.20 | +2.45 | +0.46 |

| T | +0.45 | +3.21 | -2.71 |

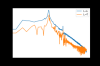

I measured the trasfer function from L,T to L,T respectively.

The pictures was attached.

I concluded it was good at some extend.

The measurement seems to go fine and is mostly finished.

However, because of the new failure of air conditioning the temperature and humidity increased quite a lot in TAMA.

It's about 30deg in main building and quite more inside clean room.

just for safety I turned off PCI laser.

Mitushahshi

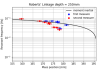

I summarized the tabletop experiments of Roberts' Linkage.

What I did

The followings are what I did.

- I measured the resonant frequency of Roberts' Linkage with changing COM.

- I checked the difference of resonant frequencys between x-axis and y-axis(The definitions of these axes are written on below sentence).

Set up

I attached the picture(Fig1).

The Roberts' Linkage was shaked by coil magnet actuator powered by FFT analyzer.

The displacement of it's was detected by photo sensor.

I measured the transfer function from coil magnet actuator voltage to photo sensor read out voltage.

Measurement results

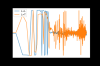

Firstly I mentioned resonat frequency and COM position. I attached the picture(Fig2).

The results says that the resonant frequency get lower and lower when Roberts' Linkage was tuned at hight COM points.

The gap are there between first mesurement and second measuremt. I thought the reasons are some coupling by different tension on wires and by human error with tuning COM(this is most properly).

Secondary, I mentioned the strange peak. I attached the power spectra density plot.

The peak at 71mHz is the resonant, and harmonic of it also are there(rabeled blue).

On the other hands, the strange peak that it is not reasonable by above mention also are there(label green).

The paper "F. Garoi et al., Passive vibration isolation using a Roberts Linkage, Rev Sci Instrum 74, 3487-3491(2003)" reported that there are cross coupling.

So I measured the x-axis and y-axis resonat frequency. The definition of x-axis is following on the road of 20m interference site(Fig3).

I attached the results. The red one is x-axis, and the blue one is y-axis.

I realized that these axes have a difference resonat frequencys, and conclued that the strange peak is from y-axis' resonant frequency (cross coupling).

[Aso, Marc, Michael, Rishabh]

We installed spare ETMY with ears up (ie reversed top/down with respect to KAGRA installation) on the translation stage.

It helped a lot to remove the front top right metal support looking from the laser side for the installation.

After small realignment of the 2 photodetectors I checked the mirror center by trying to find the position where the signals drop to 0 (ie edge of the mirror).

X_center = 393.5 mm and Y_center = 155.5 mm.

Then I started measurement with Spol at the input (HWP = 351.2 deg) with maximum AC and DC dynamic range (1V) to take map over 70 mm radius with 1 mm step.

I'll keep these settings during holydays to avoid saturation.

The measurement seems to go fine and is mostly finished.

However, because of the new failure of air conditioning the temperature and humidity increased quite a lot in TAMA.

It's about 30deg in main building and quite more inside clean room.

just for safety I turned off PCI laser.

I realigned the beam at normal incidence using the razor blades using input power of 1.59mW.

After realignment, I got angle of incidences of 0.009 deg and 0.0059 deg for vertical and horizontal direction respectively.

I tuned the input HWP and QWP to have input s polarized light by minimizing the p polarization component.

With current configuration, 'DC' corresponds to S pol and 'AC' to P pol.

I took 10mn of data with each polarization to finalized the setup calibration.

I was planning to measure the ILM sample birefringence but could not find suitable holder (30mm diameter ; 15 mm thickness).

We plan to start instead with spare ETMY measurement.

I reinstalled the output cross-polarizer and also installed a HWP (WPQ-10640-2M from SigmaKoki) just after LC2.

I am now scanning the LCs voltages with various step to measure birefringence in 'electronic Soleil-Babinet' mode.

The measurement started in elog 3295 finished.

It consists of about 6.3 millions couples of votlages applied to LC1 and LC2.

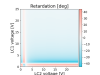

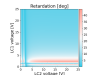

Figures 1 to 3 reports the resulting polarization states which is similar to previous measurement despite the 90 deg rotation of LC1.

Somehow we have an overall phase difference of 90 deg as before. I'll cross-check simulations.

When measurement finished, the LCs temperature was about 31degC. This indicates a stronge heating as the usual LC temperature is about 24 degC before heating for temperature control.

This seems to be related to the air conditioning failing noticed by Takahashi-san that could also explain the strange power fluctuations of the FDS laser reported in elogs 3306 and 3307.

8/1 [Chien-Ming and Hsun-Chung]

We measured around 5.4dB squeezing and 11.4dB antisqueezing at 25mW green pumped,

and 5.7dB squeezing and 16.7dB antisqueezing at 40mW green pumped.

Without green pump, OPO T=7.107 kOhm; BAB=192mV, p-pol PLL: 225MHz

At 25mW pump, OPO T=7.118 kOhm; BAB max=1.27V, min=80mV, p-pol PLL:165MHz

Nonlinear gain=6.61

At 40mW pump, OPO T=7.120 kOhm; BAB max=3.28V, min=40mV, p-pol PLL:130MHz

Nonlinear gain=17.08

The SHG power in front of MZ drops to 151.5mW today.

In addition, we found the LO power to HOM also drops to 1.68mW. We can't increase it by alignment, so we have to replace the OD0.3 ND filter before IRMC to OD0.1.

As a result, the LO power is restored to 1.94mW.

We suspect that the output power of the main laser may be continuously decaying, causing the SHG and LO power to drop!

Attached are two squeezing measurement at different pump powers. It is worth mentioning that when the HOM DC cable is too close to the oscilloscope, some noise peaks will appear obviously, especially on dark noise.

The units setting parameters of SR785 was also attached.

7/31 [Chien-Ming and Hsun-Chung]

We investigate the reasons for the squeezing level decline on 28th July http://www2.nao.ac.jp/~gw-elog/osl/?r=3305.

Originally we suspected it was caused by poor cleaning of the optics, but today we found out that the phase-matching temperature of OPO is not at the optimal value.

On 7/28 we set OPO T=7.159 kOhm with 25mW green pump and T=7.184 kOhm with 40mW green respectively in order to lock the p-pol at 270MHz.

Today we check that the optimal value of OPO T should be set near 7.107 kOhm to achieve the maximum nonlinear gain.

OPOT=7.107k; 25mW green; BAB Max=1.26V; p-pol=33MHz*5=165MHz.

Without green; BAB=196mV-6mV(Background)=190mV; p-pol=49MHz*5=245MHz.

Therefore the nonlinear gain=6.63 at 25mW pump.

HOM visibility:

LO at AMC: TEM00=5.96v; hom=2.4mV+2.4mV; mode-matching: 99.92%

BAB at AMC: TEM00= 196mV; hom=6.4mV+1.8mV; mode-matching: 95.98%

SHG output power in front of MZ drops to 165.5mW even if the SHG temperature and alignment are optimized (194.9mW on 7/28)

We preset the SR785, however, the parameters are incorrect so the squeezing measurement is weird today.

At first, the SHG is 119.7mW in front of MZ.

We correct the HOM DC balanced from -10mV to 0mV by fine-tuning HOM BS Yaw.

Hsun-Chung bought some glass dropper bottles to hold acetone (buy from HANDS).

We cleaned some optics on the optical path of HOM and SQ and then checked the BAB alignment at AMC.

TEM00=206mV; hom=5.6mV+5.6mV; mode-matching:94.8%

In the beginning, the OPO T was 7.117k(p-pol is 270MHz) with pump 25mW, the BAB max=52mV, min=24mV.

After setting the OPO T to 7.159k(p-pol is 270MHz), the BAB max= 952mV, min= 104mV

At the 25mW green pump, we measured 4.47dB squeezing and 8.43dB anti-squeezing which is worse than yesterday's result.

Therefore, those optics may not be cleaned well.

Then we measured twice FIS at the 40mW pump, got 5.28dB SQ and 12.13dB Anti-SQ at first, and 5.29dB SQ and 11.65dB ASQ at second.

Before the second measurement, the MZ failed to lock again. The reason is that the output power of the SHG seems insufficient (100mW in front of MZ).

By setting the temperature of SHG from 3.158k to 3.123k, the green light in front of MZ becomes 194.9mW.

The BAB max=1.54V and min=152mV at 40mW pump and OPO T= 7.182k (p-pol is 270MHz).

Without green pump, the BAB=234mV at OPO T=7.121k (p-pol is still 270MHz)

Therefore, the nonlinear gain is 6.58 at the 40mW pump.

The attachment is the comparison of the measurement data for two days

7/27 [Chien-Ming, Hsun-Chung]

Summary:

We measured about 5 dB squeezing and 11 dB anti-squeezing at 25.1mW pump power.

Current parameter settings:

| DDS1 | ch1 | SHG & IRMC demod. | phase 140 deg. |

| DDS2 | ch2 | GRMC demod. | phase 200 deg. |

| DDS3 | ch3 | P-Pol PLL |

54MHz (0 mW green) 38MHz (25 mW green) |

| DDS3 | ch1 | homodyne phase |

SQ: 75 deg ASQ:140 deg |

Details:

| ch1 |

| ch1 |

CC light is not coupled into the OPO at all, after realignment

CC: TEM00=19.8mV; hom= 4.6mV+2.2mV; mode-matching: 74.4%.

SHG output power dropped to half, so we realign the incident 1064nm again, and now the green power before MZ is 126.7mW.

When the green light is well coupled into OPO, the GRMC and MZ are not easy to be locked. Seems to be interference from the feedback light.

When put the LO flip mirror back, the LO light is not coupled into the 2nd HOM PD at all.(but it worked yesterday)

We have to adjust the lens position to achieve HOM DC balance.

The BAB nonlinear gain today without green and with 25.1mW green again: (this time we have considered the background by blocking the BAB.)

without green, Max=240mV-6mV(BG)= 234mV ; OPO T:7.117

with 25.1mW green, Max=1390mV (Min=96mV) ;OPO T:7.119

|

SQ: 75 deg ASQ:140 deg |

| Pump power (mW) | 0mW | 25.1mW |

| OPO temperature (kOhm) | 7.117 | 7.119 |

| P-Pol PLL frequency (MHz) | 270 | 190 |

| BAB maximum (mV) | 234 | 1390 |

| nonlinear gain | 1 | 5.94 |

|

SQ: 75 deg ASQ:140 deg |

cc1 cc2 can be locked smoothly.

cc1 error signal EPS1OUT Vpp=266mV.

cc2 error signal EPS1OUT drifts up and down over time in the range of 348mV, the Vpp is around 170mV.

The parameters we use for SR785 are:

128Hz~102.4kHz AC

FFT1 LogMag Hanning

Compute Avgs: Yes; type: Exp./cont; # Avgs: 100 ; Display Avg: RMS

SAVE: Display to Disk

|

SQ: 75 deg ASQ:140 deg |

|

SQ: 75 deg ASQ:140 degS |

[Chien-Ming, Hsun-Chung]

To check the alignment of green pump to OPO, we measure the nonlinear gain of BAB maximum in 1st HOM PD.

without green, Max=248mV (forgot to subtract the background); p-pol PLL 270MHz; OPO T:7.127

with 25.1mW green, Max=1540mV (Min=120mV) (also forgot to subtract the background) ; p-pol PLL 190MHz; OPO T:7.129

after two hours..

with 25.1mW green, Max=1200mV (Min=120mV) ;OPO T:7.129

I realign the green to OPO and adjust temp. of OPO

with 25.1mW green, Max=1580mV (Min=120mV) ;OPO T:7.123

without green, Max=248mV; OPO T:7.122

| green power (mW) | 0mW | 25.1mW |

| OPO temperature (kOhm) | 7.122 | 7.123 |

| p pol PLL frequency (MHz) | 270 | 190 |

| BAB maximum (mV) | 248* | 1580* |

| nonlinear gain | 1 | 6.37 |

*This value does not check and subtract the background caused by p-pol.

To optimize HOM visibility, we realign the OPO output BAB mode matching at AMC.

Before: TEM00=164mV; hom=34mV+8mV+8mV ; 76.6% mode-matching

After: TEM00=218mV; hom=8mV+8mV ; 93.2% mode-matching

Realign the IRMC mode matching by monitoring the T of IRMC servo

Before: TEM00=920mV; hom=48mV+48mV; 90.6% mode-matching

After: TEM00=960mV; hom=56mV; 94.5% mode-matching

IRMC PDH signal and SHG PDH signal are using the same DDS channel to demodulate, so readjust the DDS phase from 110 to 140 degrees to reach a compromise. (Used 160 degrees to reach the best SHG PDH signal yesterday)

LO mode matching at AMC

TEM00=6.64V; hom=16mV ; 99.76% mode-matching

GRMC failed to lock again, checking the PDH signal and reloading the DDS2 to change the phase of GRMC demod. from 165 degrees to 200 degrees (Used 100 degrees yesterday).

7/25

[Chien-Ming, Hsun-Chung, Marc, Michael]

We realign the P-pol and BAB by using the steering mirrors before PBS

p-pol :

Before: TEM00=1.78V; hom=460mV+100mV ; 76% mode-matching

After: TEM00=1.92V; hom=160mV+160mV ; 85.7% mode-matching

BAB :

Before: TEM00=1.05V; hom=264mV+200mV+180mV+140mV+50mV=834mV ; 55.7% mode-matching

After: TEM00=1.17V; hom=232mV+200mV+200mV+140mV+50mV=822mV ; 58.7% mode-matching

To check the green pump to OPO alignment, we use BAB to optimize the nonlinear gain.

Without green, we phase lock the p-pol at 270MHz and tune the OPO temp. from 7.147 to 7.123.

we obtain the maximum BAB output by putting the power meter before homodyne BS.

The value is 1.78V - 900mV(background) = 880mV (however, power meter is set at 532nm)

When we want to introduce the green pump, we failed to lock GRMC and MZ, also the SHG output is not good.

So I realign the SHG input 1064nm beam,

Before:TEM00=1.58V; hom=1.28V; 55.2% mode-matching

After:TEM00= 354mV; hom:10mV; 97.3% mode-matching

Then I check the PDH signal of SHG and optimize it by changing the phase from 110 degrees to 160 degrees.

I successfully locked SHG. The power in front of MZ is 132.6 mW.

Then I check the PDH signal of GRMC, it's quite small, the S/N=280mV/50mV ~ 280mV/100mV.

Optimizing this signal by adjusting the mirror at the GRMC input reflected beam and then reloading the DDS2 to change the phase of GRMC demod. from 165 degrees to 100 degrees. We obtain the S/N= 126mV/15mV.

Finally, we successfully locked GRMC after adjusting the parameters of the servo.

After locking the MZ, the pump power corresponding to the MZ offset is as follows:

| MZ offset | Green pump power |

| 4.0 | 15.7 mW |

| 4.1 | 21.6 mW |

| 4.2 | 27.0 mW |

| 4.3 | 32.3 mW |

| 4.4 | 37.8 mW |

| 4.5 | 43.4 mW |

| 4.6 | 49.0 mW |

| 4.7 | 54.6 mW |

| 4.8 | 59.6 mW |

| 4.9 | 64.9 mW |

| 5.0 | 70.1 mW |

I scanned LC1 and LC2 voltages from 0 to 25V with 0.02V step at 30degC.

Today I rotated LC1 by +90 deg to investigate the phase difference with respect to simulation.

I started measurement between 0 to 25V with 0.01V step at 30degC.

I tried to generate again polarization states but this time with 0.01V increment instead of the previously used 0.05V.

Because of TAMA visit I had to turn off the laser before the several days long measurement finished.

In any case, the results shows again good agreement with previous results and simulation and also higher polarization states coverage.

This result can be compared with simulation were I assumed for now same retardance vs voltage and extinction ratio equals to 1.

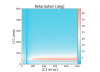

The rotation and retardation are shown in figures 1 and 2.

The retardation agrees really well with measurement if we wrap the measured retardation to positive values (fig 3).

Forthe rotation, it seems we have some kind of 90deg offset. I'm wondering if it could be because the first LC is rotated by -45deg instead of +45deg.

[Chien-Ming, Hsun-Chung, Marc, Michael]

First we found out that the power just after SHG is a bit lower than usual (measured 216mW) so we might have to tune its temperature.

Then, we found that MZ and GRMC were quite misaligned (especially in pitch).

We placed a power meter in transmission of GRMC to realign them.

First, the power had some periodic increase so we reduced the MZ scan period from 10 to 0.

Also, realigning it helped. After realignment we got :

1st arm TEM00 2.54V ; hom = 0.18V : 93% mode-matching

2nd arm TEM00 308mV ; 3 hom each = 6.4mV ; 94%

We tried to lock GRMC and MZ but the lock was not stable. So we had to increase the gains as follow:

increased GRMC gain to 3.1 from 1 ; increased MZ gain from 1 to 3

Finally, they locked and with MZ offset 4.54 we measured 44.7mW in transmission of GRMC in good agreement with the expected value.

After spending a lot of time generating polarization states and rotating the output polarizers I found out that this method is not too precise.

While the overall shape is similar to simulation, there are several points were the fitting is failing and gives polarization rotation 0 or 90 deg and retardation 45deg.

This is especially annoying as the measurement is far longer than expected (poor vi implementation limited measurement speed to 6Hz and need to rotate at least 36 times the ouput polarizer)...

In the end I removed the ouput polarizer and used the polarization camera readout.

THe measurement are agreeing now really well with simulations.

Note that in the simulation an arccos of the retardation limits the retardation to positive values only.

This result can be compared with simulation were I assumed for now same retardance vs voltage and extinction ratio equals to 1.

The rotation and retardation are shown in figures 1 and 2.

The retardation agrees really well with measurement if we wrap the measured retardation to positive values (fig 3).

Forthe rotation, it seems we have some kind of 90deg offset. I'm wondering if it could be because the first LC is rotated by -45deg instead of +45deg.