NAOJ GW Elog Logbook 3.2

Members: Sakai-kun, Manuel

In order to make maps of samples, we made a labview VI that moves the translation stage in 2 directions (namely scan and shift), reads the lockin amp values and put the data in a file.

In attachment the pdf of the front panel and the block diagram.

- Status of assembly

The moving of laser and optics according to Matteo/Eleonora new scheme is started.

We need to check the polarization used/to be used on the bench (is it OK to

work with S-pol?).

Need to check cables behind the lasers. Do they interfere with the beam?

Need to discuss with Matteo and Eleonora.

Yuefan will continue the assembly and fix the lenses required.

- Mode cleaners for 1064 nm and 532 nm

Mechanical design received from Trento. Looking for a company that can produce

them (with the help of Akutsu/ATC).

Curved mirror (1m ROC) may be bought from CVI (Raffaele contacted them)

Trento bought flat mirrors from Opto Sigma.

We can do the same but we need to fix the finesse and the polarization so that

we can fix the coating specifications (to be discussed with Virgo people).

PZT from PI. Raffaele will send the reference to Tatsumi-san to order it.

Viton o-ring to keep the mirror at the good position and allow position control

of the curved mirror. Raffaele will send the reference to Tatsumi-san to order it.

- Height of table and window

Window on vacuum chamber is at 1190 mm. Table is at 900 mm (so beam is at 973 mm).

Three beams need to enter from the window (two squeezed beams at 1064 nm and one

green beam at 532 nm). We would like to avoid periscopes and minimize losses.

So we would like to increase table height by 217 mm so to have the beams at 1190 mm.

Tatsumi-san will investigate what is the solution used in KAGRA.

- Window size

We need to pass three beams through the window.

Yuefan measured the size of the present window.

Size of present window is probably too small.

Larger size is possible. Maybe 9 cm. Is it OK?

The mechanical design used for the KAGRA windows was provided by Autsu-san.

We can start from there. Once the mechancial design will be fixed

we can fix the optic design (diameter, thickness, wedge) and ask

quotation to Sigma Koki.

Sakai-kun found that one of the arms of the translation stage was not moving properly, the step motor was turning but the long black screw wasn't. I found that the grub screw (see the picture) was loose. I checked the other arms and found another loose screw. I guess the company that cleaned and greased it forgot to re-tighten those screws. I tightened them all. Then, by using the Zaber consol, I reset the lockstep of the couples to make them move together again.

1) Glueing Related Things

1-1) Checked the current situation.

One magnet and one stand-off (wire-breaker) should be glued on the BS mirror.

1-2) Got an adhisive of MasterBond EP30-2

Via Hirata-san I got a set of MasterBond EP30-2.

Now it is storaged at TAMA center room.

1-3) Remaining missing part is weight scale.

Takahashi-san will give us. Yuefan, please receive it from Takahashi-san.

1-4) Glueing work will start from 13:30 of 7th November.

2) Suspension Related Things

2-1) Suspension JIG for double pendulm:

Takahashi-san will send back to TAMA from KAGRA site.

An expected delivered date is 9th November (Wed).

2-2) By using dummy mass, Tatsumi will set the hanging wires.

I confirmed that tungsten wires are existing at TAMA.

Expected date for this wotk is 13:30 of 11th November.

2-3) Scheduled date to be install the BS suspension is 16th November.

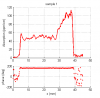

I did some calculations on the displacement-noise properties of PR3 by using the yaw-noise data measured in April this year from Akutsu-san on the respective OpLev. These calculations should show how the outcome of a length-sensing OpLev-QPD would be influenced by the noise of itself and its surroundings.

It seems by using a lens with f=500 mm we would reach the requirement of measuring at least 1um shift of the mirror. The big feature around 1Hz is due to the Kumamoto earthquake that happend in the period of data-taking.

However, this are just short-term spectra and still it is not quite clear whether such a lens can be installed.

please note that by using a lens with a smaller focal length, the noise spectrum would increase with a factor (900-f)/f, where 900 is the distance between mirror and lens (in mm as f is given in mm too).

Simulations have been done assuming a misplacement of the WAB of 2mm in x and y direction (z is the direction of the main beam) and 1 degree rotation around x and y axis.

The assumptions of shift and rotation are based on the maximum tolerable misplacement of any baffle in KAGRA.

Result: no important impact on the sensitivity of the interferometer has been found.

However, the effect on the power due to the rotation turns out to be 10000 times stronger than due to the shifting!

I ordered the attached parts for SHG housing.

Expected deliver date is 28 October, 2016.

The installation of an "upgraded" version of the OpLevs toward a low-frequency yaw- and length-sensing kind of OpLev has to be done for all main mirrors in KAGRA. However, the PR2 chamber is different from all the other chambers as there is only one viewport available for the (external) OpLevs.

In order to measure the reflected OpLev beam, we either have to install the beam collimeter inside the PR2 chamber so that the reflected beam goes through the only viewport outside, or to install a mirror in the inner wall (proper positioned), so that the beam, coming from outside, is subsequentally reflected directly toward the viewport.

I checked therefore the feasiblity of the second option by using the actual (as I hope) drawings of the PR2 chamber and the payload. It seems that, taken only the drawings, there is no reason why it shouldn't work. I prepared some pictures to see the paths of the OpLev beam (green line) within the chamber. By installing a mirror, it may be possible to guide the reflected beam toward the viewport.

However, there is still an open question how much space the additional structure on the inner wall (small mirror + mount) will take and whether or not it will collide with the main beam passing PR2 chamber toward the BS.

I packed our SHG housing for modification by a company.

Both PZT (mirror) box and heat sink are remained at NAOJ.

I upload a PDF file of

drawings and Parts list for SHG housing

I got a picture from Manuel.

Sakai-kun set the new computer inside the clean booth, plugged all the instrument and installed the software to control the absorption system.

The new computer is a PC desktop with Windows 7 64bit in Japanese. The license doesn't allow to change the language, but we could install Labview 2016 in English, at least.

We use a GPIB to USB adapter to control and read the Lockin amplifier. We found a library for the sr830 here, and used the examples to build our VIs.

The main VI is "Stanford Research 830 Acquire Measurement - X Y DC Freq.vi" and it uses the subVI "Read X Y DC Freq.vi"

The subVI "Read X Y DC Freq.vi" sends one single "SNAP ? 1,2,6,9" command to the lockin and reads the output through the GPIB port. The output of this subVI is a cluster of data with X,Y,DC and Frequency values.

The main VI initializes the lockin and set the parameters. Then uses the subVI "Read X Y DC Freq.vi" in a timed while loop (100ms for each loop), and put the read values in a shared variable. This VI can also save data in a file.

Keeping this VI running in background, we have the shared variable updated each 100ms, so we can run other VIs to use the values of the shared variable to show real-time charts or to make scans.

The "VI Show X Y DC Freq.vi" gets the values of the shared variable each 100ms and plots the X, Y, AC, Phase, DC and Chopper frequency.

We have two sapphire samples with the dimensions of Tama mirrors.

To measure them, I fixed a horizontal translation stage at the optical board and placed the mirror mount on top of it.

The first Idea was to make a scan by moving the translation stage manually (by using its micrometer screw) and taking a measurement every 5mm.

Then I realized that I could replace the micrometer screw with one of the 3 step motors of the XYZ translation stage of the PCI system, and doing so, I could make an automatized scan of the samples with the original software of the PCI system.

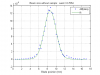

Before making the measurements I made a calibration scan of the bulk reference and found the usual value R=0.5W-1. This value is for silica, to use this calibration for sapphire samples we have to add a factor of 3.34. This correction factor was provided by the SPTS company (Alexandrovski)

The position of the Imaging Unit is corrected by 25.9mm according to the formula SampleThickness*(n-1)/n elog entry 294

I manually moved the tama sapphire sample in order to have the pump at the center of the sample.

The scan gives a good SNR and the result is 50ppm/cm for both the samples with some zone with higher absorption.

I had some trouble with the OXIDE laser 1064nn. When I change the computer to control it, I got a communication error with the serial port RS232.

This is the correct procedure to restart the laser and reestablish the communication with the computer.

1. Please turn off the all the elements. (PC, main switch of Laser,

key switch of laser) 2. Disconnect USB-serial port from the PC.

3. turn of PC

4. Connect USB-serial port to PC and check corresponding COM port at

device manager.

5. Start software

6. set corresponding COM port

7. set save file for log (This process must be done, otherwise the

software does not work properly.) 8. Turn on main switch of the laser

==> after a few moment the communication between laser and PC

would be established.

==> If the communication would work properly, turn on the key switch.

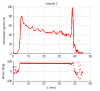

The accuracy of previous measurements could be affected by stray light coming from the high power pump laser.

I carefully checked the photo-detector ad I found two small filters inside a threaded pipe attached in front of the detector. They are supposed to suppress the stray light signal.

Those filters are Heat Absorbing Glass:

- 3 mm-thick KG-3 glass. It filters out 1064 nm http://www.edmundoptics.com/document/download/352659

- 2.5 mm-thick R-60 glass. It is the red-color filter used to block most of daylight. http://www.edmundoptics.com/optics/optical-filters/longpass-edge-filters/longpass-glass-color-filters/66043/?print=Pdf

In order to check if the pump stray light is well stopped by the filters, I switched off the probe (to avoid to have any true absorption signal, in purpose) and see if there is a different signal with and without the pump laser.

Since switching the probe OFF makes the DC signal almost 0, I don't divide the AC signal by the DC.

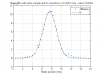

I took 1h of data with the pump ON; and 1h of data with the pump OFF. I attach the plot of the raw AC signal (X and Y) in the two cases, red and blue clouds of points.

The standard deviations of the X and Y signals are 1microV in both clouds. The difference between the means of the two clouds is 0.2microV.

Comparing with the order of 50microV of last absorption measurements, I conclude that pump stray light don't contribute to the signal.

with Mathematica software, I derived the Image Unit position correction formula:

SampleThickness*(n-1)/n

I used the ABCD matrixes of the absorption bench system and the equations for the q parameter.

I cannot attach a .nb file, so I attach the pdf of it