NAOJ GW Elog Logbook 3.2

Michael and Yuhang

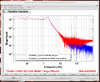

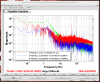

Following the method provided in Marco Thesis, we made a phase noise measurement for AFG3251. We take signal from DDS as a reference signal, since it was reported from Marco thesis that this is a stable signal source. We will check the phase noise of DDS later.

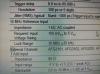

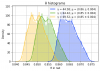

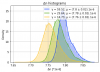

The measurement was to use DDS and AFG3251 to generate 20MHz signal and acquire their beatnote after low pass. We tried to synchronize them with another DDS channel to provide a 10MHz signal to the 'external reference input' channel of AFG3251 (Fig. 1 and 2). However, the 20MHz between them cannot be synchronized. In the end, we tune DDS to be 20.00073506 MHz to have beatnote signal as flat as possible. In the end, there was still some very low frequency component was not removed (Fig. 4). Then we took measurement of beatnote with different frequency band using network analyzer.

To calibrate the measured beatnote signal, we increased DDS signal frequency by 1kHz. Note that we used DDS channel with amplitude reduced by a factor of 2 to avoid saturation. And we found pk-pk beatnote is 0.316V. Therefore, the measured beatnote spectrum need to be divided by (0.316/2).

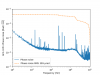

The phase noise is shown in Fig. 3. The integrated phase noise from high frequency to 10Hz is 399urad, which is slightly higher than the measured DDS phase noise (reported to be 117urad from Marco thesis).

Abe, Marc, Matteo

We restarted the setup after the electrical blackout.

We installed shinkosha 7 on the translation stage and started to check the input polarization.

However, it seems that there are some issues with the Zaber encoder so we need to home every motors of the translation stage.

Abe, Marc

In order to get the correct limits of the translation stage we had to home every motors.

Thanks to the help of Michael and Yuhang we removed the shinkosha 7 and placed it back after this operation.

Then we set correct Z limit (25 mm to 100 mm).

We checked the AC (measuring s pol) and DC (measuring p pol) alignment, maximal and minimal values without mirror.

We installed the mirror and realigned the 2 PSDs.

We started a polarization measurement with s polarization at the input and from X = 398 to 470 mm and Y = 20 to 235 mm that should allow us to see border effects.

(the mirror center is X = 398 mm and Y = 122 mm).

The GRMC/MZ servo was suspected to have issue, but it was found that GRMC works well in elog2741. This indicates the problem comes from MZ servo.

I asked Pierre for some suggestions. Especially, I found the enable signal from MZ servo is always around zero. Pierre suggested me to check the resistance of MZ servo while MZ servo is not powered. I did such check and found there is a resistance of 67kOhm. At least there is no short cut.

I did similar check as elog2713, I found that the signal coming from GRMC ref PD has no signal. Then I checked the PD and found it is not powered! This is very strange because the switch of this PD is very hard to reach. But anyway, by switching on GRMC ref PD, I could lock GRMC and MZ again. Now there is no problem at all for GRMC and MZ.

Although this is just a stupid issue, but during the check of GRMC, I found out it is very necessary to record the level of signals for each control servo. These values will be very essential for trouble shooting in the future. I plan to make a list of all useful channels of these servos soon. On the other hand, elog2741 is a standard way to check servo and can be useful for future check as well.

Michael and Yuhang

Yesterday, we finally aligned back filter cavity. During the recovery phase, we found the camera driver used for intra-arm second target is broken. We replaced it with a driver labelled with 'PRM surface'.(fig1,2,3)

We also found the motor C of END mirror picomotor is broken. This motor was used for adjusting END mirror pitch (fig.4). But we can use the motor B for pitch temporarily since these motors are just used for sending signals with particular IP address (fig.5). The signal to be sent to picomotor is decided by ourselves from LABVIEW.

Michael and Yuhang

We reported an issue about not being able to lock GRMC one month ago in elog2713. We asked Pierre for some suggestions of testing the servo. He recommended to take GRMC servo out and use a SR560 instead of the plant in the opto-mechanical control loop. The setup of this test is sketched as the attached figure 1.

The results are briefly summarized in Fig.1 as well. We found that if we don't send signal to TRANSMIS IN and use MAN mode, we can successfully lock control loop. However, using a positive 0-2V sinusoidal signal with period of 1s can cause the lock/unlock of the loop in AUTO mode. Note that a threshold is chosen at -0.4V. We also found that if we use a positive 0.9-1.1 V sinusoidal signal with period of 1s, we can keep the loop locked in AUTO mode. This test verified that GRMC control servo should work well.

In fact, we succeeded in locking GRMC afterwards without the signal from MZ servo going into GRMC servo's ENABLE IN. Once the ENABLE IN channel is connected to MZ servo, GRMC loop cannot be locked. We checked also that this signal is always zero. Therefore, we suspect the issue comes from MZ servo now. More test will be done to test MZ servo.

Yuhang and Michael

During the recover of filter cavity facilities, we found a router is broken. This router is used for intra-arm second target remote control and pico-motor control. It is essential to repair it.

Accidently, we found a new router around. After just replacing the old router with a relatively new one, the router works again. (new and old routers are shown in the attached figure 1, we can see the old one shows very yellow)

The old router is labelled with a piece of pink tape with broken written on top.

Same as previous entry but the sample was rotated by 180 deg (estimated by eye)

Using the new code (cross-checked with Shinkosha 7 results)

Remember that here DC corresponds to s pol and DC gain should be 10.

The height of the first steering mirror and PSD is 110 mm for BS and Input and 115mm for PR.

For End, the height of the first steering mirror is 110 mm while the PSD height is 90 mm (maybe a reason for the strange behavior of this oplev?).

I'll try to tune it after the FC recovery (we had a black-out on Saturday).

I also fixed the ND filter of the BS oplev that was not fixed.

I only just remembered this but we also measured the beam height (70mm) before and after the Faraday assembly, as shown in the photos.

We had blackout on 20211113. Today, we recovered facilities in TAMA and found one of the turbo pumps got error.

To recover vacuum system, I firstly turned on rotary/dry pump and wait for a few minutes and open the gate valve between rotary/dry pump and turbo pump. Then I turned on turbo pump.

The error happened only for the turbo pump in the middle of arm. And it happened few minutes after I switched it on. The large noise was heard from it. The error code is E089 shown on the screen of turbo pump controller.

I checked online, the E089 indicates that rotor is outside its nominal position.

That looks very good, indeed!

What you can do in addition is to check for the second (negative) solution according to theory, as I reported last meeting.

An important point is also to be very precise with all input parameters. For example, it isn't enough to set the thickness to just 6cm or so but to take into account the refraction due to the inclination and the hence extended beam path.

Katsuki, Marc

We measured first the surface calibration R_surf = 17.13 /W with z = 42.75 mm, Ziu = 66 mm and Pin = 24.2mW.

Then we measured bulk calibration R_bulk = 0.7474 cm/W with z = 41.85 mm, zIU = 65.68 mm, Pin = 23 mW and Pt = 11.8 mW.

We installed the evaluation plate 14 and found X_center = 397.5 mm, Y_center = 112.469 mm.

We increased the power to ~1W and could clearly see the 2 surfaces from Z_scan which gave Z_center = 53.875 mm.

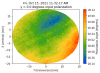

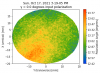

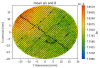

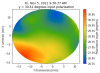

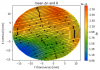

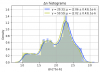

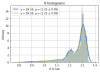

We measured evaluation plate 14 absorption with Pin = 1.153W and Pt = 0.985W (fig 1).

The map is 70 mm radius and 1mm step size and lasted ~5h30.

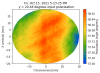

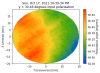

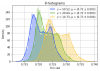

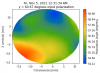

We installed the evaluation plate 11 and confirmed the same Z_center position with a Z scan. Absorption measurement (fig 2) was performed with Pin = 1.169W and Pt = 1.004W.

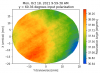

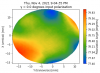

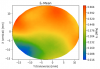

Finally we installed the evaluation plate 10, confirmed the same Z_center and measured absorption (fig 3) with Pin = 1.153W and Pt = 0.989 W.

All evaluation plate were installed with marking of ingot position on the right side (looking from the injection) so that the top side of the ingot faces the injection.

All plates show quite high absorption with the usual star pattern.

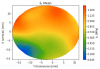

This entry reports the birefringence measurement of TAMA #1 with 1.5cm radius, 0.25 mm step size, 0.5s wait time and 0.488mW input power.

Due to time constraints only 3 measurements were possible.

Note that the AC and DC was realigned before input polarization calibration and with sample and that here 0 deg polarization angle corresponds to s polarization.

The analysis code was checked using the Shinkosha7 data and produced identical results.

The main result is that polarization, theta and delta_n are quite uniform but the main variation corresponds also to the maximum absorption (see entries 2723 or 2672) while the triangular patterns does not seem to affect significantly these parameters.

That looks very good, indeed!

What you can do in addition is to check for the second (negative) solution according to theory, as I reported last meeting.

An important point is also to be very precise with all input parameters. For example, it isn't enough to set the thickness to just 6cm or so but to take into account the refraction due to the inclination and the hence extended beam path.

Matteo, Takahashi-san, Yuhang

Takahashi-san removed the jig and released BS earthquake stop this morning. Before closing vacuum chamber, we checked transfer function of BS and pitch/yaw coupling.

The transfer funtion shows in the first attached figure. We can see that the red line is close to reference below about 10 Hz. The deviation at low frequency is probably due to the air flow, while the deviation at high frequency is presumably due to acoustic coupling.

The pit/yaw coupling shows in the second attached figure. The green shows the coupling when we have magnet drop. The red curve is after we put new BS magnet, which got close to reference (blue curve). This figure shows that the BS mirror magnet replacement work is successful.

After confirming TF and coupling, we closed both PR and BS chamber and evacuated them. Now, we are using turbo pump to evacuate. Until the vacuum level reaches about 1e-8 mbar, we will open the gate valve between PR/BS and Input.

Matteo and Yuhang

To check what is the rotation angle of the Faraday rotator, we removed the HWP after it. We found the 2nd PBS reflected IR power decreased from 458uW to 192uW after removing HWP. This tells us that the rotation is arctan((458-192)/192) = 54 degree.

By adjusting the relative position between magnet and TGG crystal, we achieved reflection 213uW and transmission 226uW. In this case, the rotation is arctan(226/213) = 47 degree.

We put back HWP after optimizing HWP and found a transmission of 6uW from the 2nd PBS. After rotating HWP, we reduced it to 4uW.

In the end, we checked round trip loss of Faraday isolator using a IR HR mirror reflecting back the reflection from dichroic mirror. We found injection of 449uW, 2nd PBS reflection of 438uW, and total reflection of 390uW. The round trip losses from Faraday isolator is 11% now.

We found out that the TAMA 1 fast axis orientation was also quite uniform and similar to the aztec sample...

Following entries will report all measurements that were taken but here we report the various checked performed :

- with 14.7 mW input power and OD 2 the maximal power reaching the QPD was below 0.6 mW (maximum recommended by Thorlabs)

- the output voltage of the QPD with this optical power is about 1.4 V (consistent with the responisitivty of the QPD at 1064 nm)

- to avoid saturation of the lockin amplifier (at 1V) we placed 6dB attenuator and the lockin voltage was indeed divided by 2

- the spectrum of the signal show clearly the peak at the chopper frequency and harmonics (note that 3rd harmonic is stronger than 2nd)

- the beams alignment before the QPDs were tuned to always be inside the sensor with and without sample

- the 2 QPDs signals have the expected behavior when changing the input beam polarization angle

- the maximum of the QPDs with sample correspond to about 0.9 of the maximum without sample (consistent with sample reflectivity checked with power meter)

- for the last measurement (will be precised in the entry) we reduced the incident power to 0.588 mW, removed the OD and the laser linewidth to avoid as much as possible possible back-scattering and recentered the beam with and without sample before every measurement

Yuhang, Michael

We took the opportunity to measure the vacuum FI loss when the vacuum tanks were opened, using BAB. The vacuum Faraday isolator assembly can be seen in the photo (figure 1). The polarizers are two mirrors tilted at 55 degrees (Brewster polarizers). The black tube is the Faraday rotator. Attached to the end of the rotator is the half wave plate. From the reflection of the second polarizer, the IR beam hits the dichroic mirror, where it is recombined with green. Instead of propagating to the filter cavity, we used a mirror (furthest left in the photo) to reflect the beam back through the Faraday. Then, we measured the power in the following locations:

P1 in: Incident power at the first polarizer, coming from the squeezer table

P1 ref: Reflected power after P1 in

P1 tra: Power transmitted through the first polarizer, with respect to P1 in

FR/HW tra: Power after one pass through the Faraday Rotator and Half Wave plate

P2 ref: Power reflected from the second polarizer after coming from the Faraday

P2 tra: Power transmitted through the second polarizer, with respect to FR/HW tr

Di in: Incident power on the dichroic mirror

Di ref: Reflected power from the dichroic mirror

RT P1 tra: Power transmitted through the first polarizer after two trips through the Faraday.

There is some weirdness with the power meter measuring more power after reflection from certain components, but it consistently happens in certain positions (P1 ref, P2 ref, Di ref), which makes us think it's more to do with the power meter geometry. It makes precise measurement of losses to be difficult. Still, we can draw two conclusions: 1) the polarizers have low transmission of the order of 1%, and 2) the round trip loss through the FI assembly is about 14%. We took several measurements at the positions that were causing problems. Also, the p-pol PLL unlocked at a couple of points (between columns 4/5, 10/11 on the table below)

Power measurement (units of uW)

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

| P1 in | 446 | 461 | 400 | 424 | 439 | 422 | 412 | 429 | 425 | 417 | 415 | |||||

| P1 ref | 448 | 434 | 437 | 427 | 427 | 428 | 426 | |||||||||

| P1 tra | 4 | 4 | ||||||||||||||

| FR/HW tra | 447 | 443 | 430 | 407 | 407 | 395 | 415 | |||||||||

| P2 ref | 432 | 440 | 330 | 413 | 416 | 404 | 415 | 412 | ||||||||

| P2 tra | 3 | 2 | ||||||||||||||

| Di in | 415 | 395 | 419 | 422 | ||||||||||||

| Di ref | 392 | 400 | 422 | 419 | 412 | 412 | 407 | 413 | ||||||||

| RT P1 tra | 377 | 371 | 353 | 355 | 352 | 357 | 372 |

Avg. RT P1 tra/P1 in = 0.857

RT P2 transmission = 2 uW

Takahashi R., Matteo, Marc, Yuhang, Michael

The BS chamber was opened and the magnet was glued.

Photos of the process are attached.

The BS vacuum tank was closed on Friday, and then the PR chamber was opened and the portable cover moved over PR.

Katsuki-san, Marc

We removed all the readout of the birefringence. The reason being that the photodetectors size was quite small wrt to the beam size. This means that performing the alignment without sample might not be so accurate for the case with sample.

First we replaced the optical breadboard from imperial holes size to metric ones.

Then we reinstalled the PBS, the ODs and tried to installed the new PSD (PDQ80A) that have quite larger sensor size but are also sensitive to visible light.

In order to have a larger beam on the PSD, we replaced the lens in front of the PBS by a 100 mm focal one.

Sadly, because the PSD sensor is 4 cm above the screwing hole, it was quite tricky to find proper post.

Therefore, we also installed 2 steering mirrors just after the ODs.

Finally, we installed laserline filters right in front of the PSDs.

We took time to put label on various cables.

The alignment was checked (ie we confirmed that the maximal power of both ac and dc is reached without sample).

I just started birefringence measurement of the TAMA T1 sample with s polarization at the input.

The 'bad news' is that the gain of the PSD requires to change the gain of both lockin amplifiers depending on the input polarizations.