NAOJ GW Elog Logbook 3.2

This entry is just a log of Today's work.

I am revising the design of folded cavity spacer.

The company will come to NAOJ on next Tuesday and I will order the spacer with final design.

After that I will upload the drawings on GWSPwiki.

[Aritomi, Yuhang and Yao-Chin]

According to the previous R&D result (entry 1616), we found some issues for old isolator (IO-3-1064-VHP) including its aperture size too small and position too far relative to OPO cavity. Today, we installed isolator (FI-1060-5SC-HP) and put closer to OPO cavity to reduce back reflection. I also checked that the input/output aperture (Ø-5mm) of isolator was larger than old isolator. Fig 1 shows new optical layout. We main installed optical elements in blue frame zone.

Because SQZ and p-pol light were different polarization after OPO cavity, we could use PBS to separate them. Thus, the p-pol light is reflected from input PBS of isolator to right angle prism mirror (MRA10-K13) and its height was 54mm as shown in Fig 2. However, the polarization of SQZ light was rotated 45 degree after isolator. We used half wave plate to rotate its polarization keeping S polarization. In addition, we also re-installed the TAMA PD's position in order to add more space putting isolator.

We also check SQZ and LO overlap by using alignment mode cleaner, moving the lens (f:100mm) before isolator to improve mode matching.

[Aritomi, Yuhang, Yaochin]

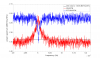

Today we installed new faraday (FI-1060-5SC-HP) between OPO and PBS to reduce back reflection from homodyne. Yaochin will report the detail. We measured frequency independent squeezing before/after installation of faraday. CC2 demodulation phase is as follows.

| CC2 demodulation phase for squeezing (deg) | CC2 demodulation phase for anti squeezing (deg) | |

| without faraday | 90 | 132 |

| with faraday | 105 | 155 |

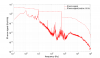

Attached picture shows squeezing and anti squeezing spectrum with/without faraday. After installation of faraday, squeezing spectrum got amazingly better. Yuhang will report the phase noise measurement.

Today I worked on the alignment for AOM.

The following is the procedure what I did.

- Adjusted the lens position before AOM in order to locate the beam waist around the AOM.

- Played with STMs and AOM stage and maximized diffracted beam power.

-

Then adjusted RF level to maximize diffracted beam power.

At that moment, the beam power input to AOM was 8.6mW and that of diffracted beam was 4.6mW.

So the efficiency was about 55%. - Then put a lens after the AOM to make collimated beam.

- Put an iris to eliminate 0 order diffracted beam and pick -1st order one.

- Put a mirror to make the reflection beam enter the AOM again.

- Played with the end mirror to see the double-passed 1st order diffracted beam.

-

Eventually I found 2 beams are picked off by PBS.

One is 0 order double-passed beam and the another is -1st order double-passed one.

I mean the former one is frequency shifted only once, and the latter one is shifted twice. - Measured the double-passed beam power and it was 2mW.

Double-passed beam has the same beam path as input beam.

I think this may be reasonable for double-pass AOM configuration.

I think the next step is to optimize the alignment to maximize double-passed beam and minimize the beam jitter.

Also I should check the spec sheet to confirm the diffraction efficiency and estimate the requirement for beam jitter.

In addition, I connected the tube between scroll vacuum pump and cryostat chamber (attached).

According to the spec sheet, the diffraction efficiency of AOM is 87.7% at 1060nm and 500um beam diameter with 1.50W RF power.

This morning, I tweaked the STMs to increase the diffracted beam power.

However the diffraction efficiency was about 50%.

I'm suspecting the beam diameter is so small that the efficiency is low.

Since I have another double-pass AOM, I will input larger diameter beam to another AOM and see the effect of beam diameter on efficiency.

Also I will check the RF power.

Simon, Pengbo

Today we started the polarization map on Shinkosha KAGRA-size sample.

First, we took the sample out of the transportation box and inspected the mirror visually, we found coating on both sides and an arrow on the barrel, which we think might indicates the HR coating. (please check the attached photo). So we place the sample with the HR side facing the laser.

Then, We measured the AC and DC value under s- and p- polarization without the sample and move the sample back to the center. Due to the HR coating, we increase the laser power to recieve a measurable signal (--> 2A input current + removing ND filters.) However, After this adjustment, we cannot confirm the polarization status becasue the laser power to too high to measure. For now, we assume it was still the p polarization and ran the map.

Apart from that, we did a test about the output beam. We put another HWP in the output beam and adjusting so that it is maximized in p polarization.

| with the HWP | without the HWP | |

| AC | 1.82mV | 1.96mV |

| DC | 33.5mV | 33.9mV |

As can be seen, the results did't change so much.

Aritomi, YaoChin and Yuhang

We closed the bench shield of main laser side(as shown in the attached picture). Now the only side we are not closing is the GR/IR injection side. Before closing, we need to drilling several holes on the board for GR/IR beam.

[Aritomi, YaoChin, and Yuhang]

After the check of frequency-dependent squeezing(reported in elog 1805), we decide that we could go on the replacement of the Faraday isolator.

But we decide that we should do the replacement after measuring again frequency-independent squeezing. So we did the thing we report here.

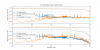

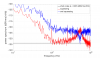

The measurement of squeezing is done with the main laser not locked to the filter cavity. And the result is attached in the first attached figure. As you can see from this figure, we could only see a bit squeezing in the high-frequency region. At the same time, we found the CC1 loop was quite unstable. So we guess the phase noise is quite high now.

So we did the measurement of phase noise. The pk-pk value of CC1/2 phase noise is as following

| pk-pk | calibration factor | |

| CC1 | 40mV | pi/4/0.04/15 |

| CC2 | 208mV | pi/2/0.079/15 |

The result is attached in figure 2. By comparing the phase noise measured before and reported in elog 1572, they are quite similar. By comparing the shape of phase noise and squeezing measurement, we also found that CC2 phase noise is dominating the measurement of squeezing.

[Yuhang, Yao-Chin]

When dithering loop was open, we recorded that IR transmission modes correspond to AOM frequency (entry 1701) without parametric amplification of BAB which power was 318 uW. The result was as follows, mode matching was around 89.9%. We could realign suspension of BS and INPUT mirrors to reduce high-order modes. After aligning mirrors and dithering loop was closed, IR transmission was 405. At same time, we observed the GR and IR transmission signals during ten minutes as shown Fig 2. After ten minutes, IR and GR were misaligned obviously with decreased 16% and 4%, respectively. The CCD camera image changed from Fig 3 to Fig 4. Today, the filter cavity was unstable.

| Mode | IR transmission (average value) | AOM frequency (MHz) | Difference -109.03565 (MHz) |

| HG00(TEM00) | 370 | 109.03565 | 0 |

| HG10 (Yaw) | 115 | 109.43133 | 0.39568 |

| HG01 (Pitch) | 100 | 109.43223 | 0.39658 |

| HG11 | 98 | 109.82843 | 0.79278 |

| HG02 | 96 | 109.82922 | 0.79357 |

| HG20 | 97 | 109.83783 | 0.80218 |

| Background | 95 |

Note: From CCD camera image showed to define mode as Fig 1.

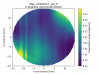

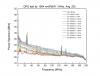

We measured the polarization map on TAMA #1 with different input polarization angles. 0 degrees represents the pure P polarization.

As can be seen, the S- and P- polarized map show apparent offset, which mainly due to the birefringence effect. In contrast, another three mixture maps show consistency with the input polarization angle.

[Aritomi, Yuhang, Yaochin]

First we checked IR mode matching again. Mode matching is 92% as follows.

| Mode | IR transmission |

| TEM00 | 365 |

| yaw | 112 |

| pitch | 98 |

| offset | 94 |

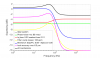

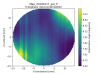

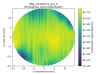

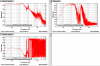

Then we measured frequency dependent squeezing around 50 kHz and 500 Hz (Pic. 1,2). CC2 demodulation phase is 75 deg for squeezing and 110 deg for anti squeezing. During this measurement, turbo pump was off and locking accuracy should be 3.1 Hz which corresponds to 3.3 pm (entry 1797). Pic. 3 shows squeezing degradation budget with current parameters.

Squeezing level inside filter cavity with 50 kHz detuning may be better due to better alignment. For FDS spectrum with 500 Hz detuning, we could observe squeezing angle rotation, but there is large phase noise below 100 Hz.

As we know, we need to align the filter cavity quite often. Sometimes we need to align many times during one day, sometimes it is stable for one day.

I took the alignment condition in the scale of the day (during October) and made this plot. We could use this as a reference for the alignment. We could have a feeling about how our filter cavity drifts for several weeks.

I worked on alignment for double-pass AOM with scanning frequency.

Since I have not prepared QPD yet, I used beam profiler to monitor the beam position.

Still the double-passed beam has beam jitter and need more optimization.

It should be noted that the input inpedance of frequency tuning is 1kOhm so that the actual input voltage from function generator which output inpedance is 50Ohm is doubled.

Tunable frequency range is 50-100MHz and it corresponds to +1.5 to +15V (+0.75V to +7.5V on display).

The attached is SMC connector to input voltage for frequency tuning.

| Mode | IR transmission |

| TEM00 | 3000 |

| yaw | 200 |

| IG20 | 140 |

| offset | 94 |

After this measurement, I checked mode matching without parametric amplification. Though IG20 was too small to be measured, mode matching was 96%.

| Mode | IR transmission |

| TEM00 | 390 |

| yaw | 100 |

| pitch | 100 |

| IG20 | - |

| offset | 94 |

Shoda, YaoChin and Yuhang

After the recovery of top coil(H1) of input mirror, we could use total four magnets to drive the length of filter cavity. Following the method of entry 1708, we calculated a driving index for input mirror. However, up to now, all the index is decided by the decouple of length/pitch/yaw at 4Hz.

The driving index is as following now

| H1 | 0.79 |

| H2 | 1 |

| H3 | 1 |

| H4 | 0.73 |

However, we could see from the following figure. We still have coupling at other frequencies.

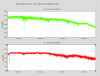

A filter improvement (suggested by Matteo B.) has been implemented for PR pitch. I also added some notch at the frequency of the main lines.

Pic 1 comparison of the filters zpk

Pic 2 performances of the new filter

It seems to work very well.

First I checked IR alignment and found that IR TEM00 transmission was small. So I tweaked steering mirrors for IR injection and could recover the good alignment. Mode matching is around 95%.

| Mode | IR transmission |

| TEM00 | 385 |

| pitch | 110 |

| IG20 | - |

| offset | 94 |

Then we measured locking accuracy again as entry 1769.

We measured the Polarization map on TAMA#1 with different polarization angles. O degrees represents the pure P- polarization map.

As can be seen, these images show the same pattern in structure. Also the S- and P- polarization both show an apparent offset, which is most likely due to the birefringence effect.

[Aritomi, Matteo, Eleonora, Takahashi]

Yesterday we opened the input chamber with the help of Takahashi-san, and we confirm the intermediate mass was touching and picomotors were at the end range. (See entry #1783)

We adjusted IM mass and moved the picomotors by hand (and josystic) to make the reflection from the input mirror to superpose with the incoming one. It was quite hard to achive the superposition as we didn't notice that the intemediate mass was touching again and the picomotors couldn't move the mirror properly. Also the gatevalve between input and BS distorts the beam and causes multiple reflection.

Pic 1 and 2 show the current position of picomotors. In the pitch case we are quite close to the end of the range.

Today, since the vacuum was restored, we open the gatevalves and we could realign and lock the cavity again.

Anyway we found that the spectrum of the pitch motion has a large, sharp peak at 9 Hz that was not there before (pic3) . The TF seems fine (pic4). I wonder if there is still a problem with IM mass. As a first step I will try to adjust the control to damp it better.

Recently we switched off DDS board many times for the sake of avoiding RF signal cross-talk.

But recently every time we switch on again DDS, we heard a strange sound. From the sound, we guess the frequency seems to be a fixed audio frequency.

Up to now, our solution is

1. switch it off the rack containing the DDS board.

2. take out DDS3 board

3. switch on the rack

4. Put back DDS3 board while the power is on

By following this procedure, we could avoid the sound problem. But we still don't know what is the reason for this sound.

[Yao-Chin, Aritomi]

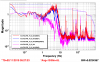

Testing method was same as entry 1785. However, we changed laser source to infrared light of 1064 nm. Infrared light hit in the first quarter of QPD2 (QPD2 input 1). We connected the corresponding DC output to the oscilloscope to check DC voltage. We also connected the corresponding RF output to a 32 dB amplifier and then check its power spectrum by a spectrum analyzer (Keysight N9320B).

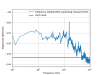

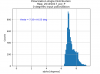

We measured the light power, DC voltage, DC current by using "PuTTY", and RF channel power spectrum with RBW of 1MHz and average 28 times shown in pic. 1. Dark noise of pic.1 included the 32 dB amplifier and instrument when no IR light hit to QPD. In this measurement, when light power goes up, power loss is going down unlike the measurement in entry 1785. Green power in entry 1785 was too much since maximum DC current is 10mA according to specification and calculated DC current is already more than 10mA with 53.5 mW of green.

Pic. 2 shows same measurement in NIKHEF. The result is similar to our result, but we have some peaks around 25MHz, 125MHz, 140MHz.

|

Light Power [mW] |

DC Voltage [mV] |

DC Current [mA] |

calculated DC current (mA) (photosensitivity is 0.55A/W according to specification) |

power loss (%) (ratio of measured DC current/calculated DC current) |

| 0.58 | 248 | 0 | 0.319 | 100 |

| 1.25 | 504 | 0.1 | 0.688 | 85 |

| 2.5 | 1000 | 0.6 | 1.38 | 57 |

| 3.7 | 1500 | 1.1 | 2.04 | 46 |

| 4.5 | 1940 | 1.5 | 2.48 | 40 |

| 7.3 | 3000 | 2.7 | 4.02 | 33 |

| 9.5 | 4000 | 3.7 | 5.23 | 29 |

| 11.7 | 5000 | 4.8 | 6.44 | 25 |

| 13.5 | 5960 | 5.7 | 7.43 | 23 |

| 15.5 | 7040 | 6.8 | 8.53 | 20 |

| 17 | 8000 | 7.7 | 9.35 | 18 |